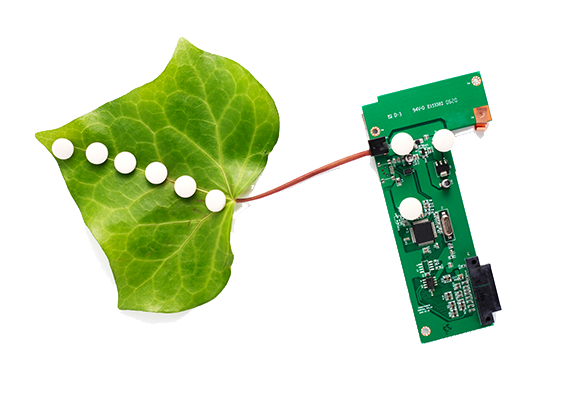

Transceiver is a device for signal conversion, which usually refers to optical fiber transceiver. The emergence of optical fiber transceiver converts twisted pair electrical signals and optical signals to each other, ensuring the smooth transmission of data packets between the two networks. At the same time, it expands the transmission distance limit of the network from 100 meters of copper wire to 100 kilometers (single-mode optical fiber). First of all, let's understand what is optical fiber transceiver. Optical fiber transceiver is an Ethernet transmission media conversion unit that exchanges short-distance twisted pair electrical signals and long-distance optical signals. It is also called photoelectric converter in many places. After knowing what is an optical fiber transceiver, let's have a detailed understanding of the working principle and usage of the optical fiber transceiver! Optical fiber transceivers are generally used in the actual network environment where Ethernet cables cannot be covered and optical fibers must be used to extend the transmission distance. At the same time, they also play a great role in helping to connect the last kilometer of optical fiber lines to the metropolitan area network and the outer network. With optical fiber transceiver, it also provides a cheap solution for users who need to upgrade the system from copper wire to optical fiber, and lack funds, manpower or time. The function of optical fiber transceiver is to convert the electrical signal we want to send into optical signal and send it out. At the same time, it can convert the received optical signal into electrical signal and input it to our receiving end. Optical fiber transceivers are generally used in pairs. For example, the optical fiber transceiver (possibly other equipment) in the computer room of the operator (Telecom, China Mobile, China Unicom) and the optical fiber transceiver in your home. If you want to build your own LAN with optical fiber transceivers, you must use them in pairs. General optical fiber transceivers, like general switches, can be used after being powered on and plugged in without any configuration. Optical fiber socket, RJ45 crystal head socket. However, we should pay attention to the receiving and sending of optical fibers, one receiving and one sending, and if not, we can exchange them.

Even though electronic components may meet testing standards in terms of basic performance after production, it is common to see some components fail earlier during actual use. Additionally, components that initially demonstrate superior basic performance can sometimes be more prone to failure. These phenomena indicate that basic performance testing alone does not fully reflect the stability and reliability of components over long-term use.Relationship Between Reliability and Basic Performance:The reliability of a component describes its ability to operate stably during continuous use. For example, while some ceramic chip capacitors may exhibit high dielectric breakdown voltages under static conditions, they might show a higher failure rate during accelerated life tests under high thermal loads. This highlights an important point: although the initial technical performance of components is crucial, if their reliability is low, these capabilities cannot be fully utilized.Importance of Reliability:Reliability is not only a critical quality indicator for electronic components but also the foundation for the stable operation of electronic devices. To enhance the overall reliability of devices or systems, it is essential to start with the reliability of each component they comprise. When selecting electronic components, such as chip resistors, chip capacitors, and chip diodes, special attention should be paid to their reliability assessments to ensure the long-term stability and efficiency of the entire system.

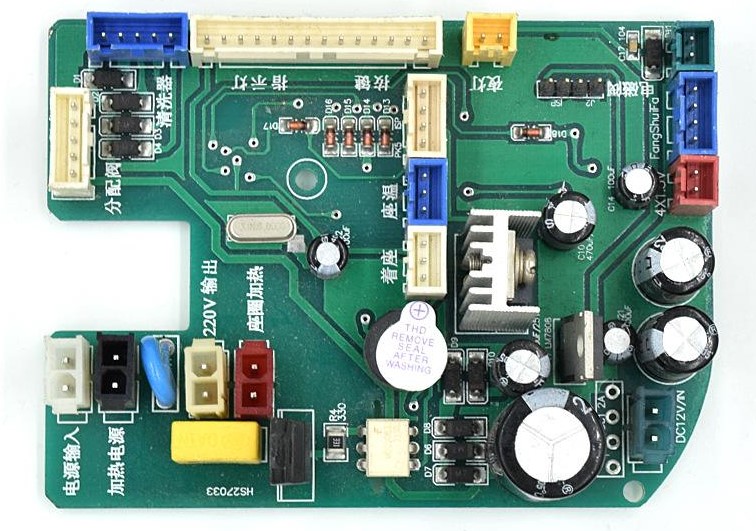

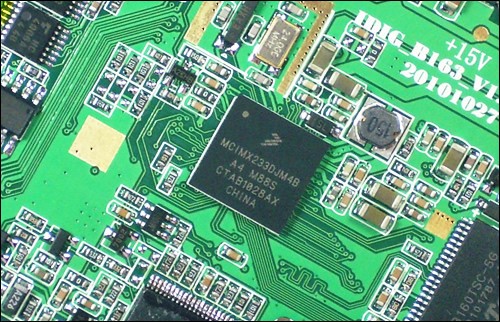

Detailed explanation of the main control chip classificationThe main control chip is the core component of the motherboard or hard disk. It is the bridge between various devices and the brain that controls the operation of the devices. In the motherboard, two chips are important. One is Nanqiao chip, which controls the expansion slot, USB interface, serial port, parallel port, 1394 interface, VGA interface, etc. it is mainly responsible for the connection between external interface and internal CPU. The other is Beiqiao chip, which controls the type and model of CPU, bus frequency of motherboard, memory type, capacity, graphics card, etc.3505, low-end chip, 3505 and 3506, 3507 add the function of line-ni to the function of 3502 (commonly known as CD direct recording function), but the music input format is wma format which is inferior to MP3 format. 3502, which is the low price in 35 series, but does not support lithium battery, has high power consumption, and has become one of the mainstream low-end products with low price. 3501 and 3502 have more programs on the market of electronic text reading function of TXT, mainly including the following categories: Philips, SigmaTel, telchips, skyark, Sunplus, Zhuhai torch, etc.philipsPhilips chip solutions represent most of the machines of iRiver (ifp100, 300, 500, 700, 800, 900, 1000 series, etc.), a810c, A610, etc. of K & C of Korea, G128, etc. of MSC. The main feature of the products using this series of chip solutions is that the sound quality processing effect belongs to the leading edge of the listed chip solutions (this is also a relative concept, because in addition to the chip, the factors affecting the sound quality also include the chip, related circuits and software processing).But relatively speaking, it is difficult to develop and the cost of the overall scheme is high. Therefore, the use of the series of programs, mainly concentrated in high-end brands.sigmateThe solution of this series of chips should be that domestic machines use more. We are familiar with MSC H128, Patriot moonlight box, and many domestic machines. On the other hand, the representative products using this solution in Korean machines are (listed are domestic brands, the actual original factory is Korean products): JNC ssf70, ssf800 (3420 chips), Samsung 55 (3420 chips). There is also a new Hong Kong brand entering the domestic market: Lauren MP3 series all adopt this scheme (6602, 6603, 6604, 6608, 6620, 6632, 6628, etc.). It is characterized by a high degree of development - at the beginning of the series, the product repair rate is high, has been quite mature, product stability is very high. The product with this scheme has a wider voice range (compared with the domestic decoding scheme), and the product quality is relatively stable. Under the dry environment in the north, the antistatic performance is strong.telechipsOne development trend of this series of chips is that the proportion of Korean machines is particularly high. We are familiar with the following products: K & C km-yf128 / 256, km-c128f, km-101, km102, km103, etc., Dec m550r, Lenovo f860, Zino z700i, MSc pn128, etc. The series of programs are also in constant development. The trend is in South Korea, and its proportion should be very good. And from the actual performance of the product, its function. In the domestic machine, the chip scheme is rarely used, and from the actual performance point of view, the performance of the machine compared with South Korea, there is a relatively large gap. In addition, the machines using this scheme basically have line in function, and the recording performance is relatively mature.skylarkRepresentative products include MPIO fl200 and the "round hanging series" produced by a large number of domestic enterprises. Wma does not support, is a big weakness of it, but the volume can be very small.Actions 2075 and 2085 atj2089 / 2087 (more used in high-end computers).2075 and 2085 are more used in domestic low-end machines, 2085 is USB2 more than 2075. 0 support. Set MP3 player, flash disk function, DVR format file support, AB reread, LCD display function, the sound quality is slightly inferior to sigma Tel, repair higher.SunplusSunplus: spca514a / spca751aThe price is cheap, the domestic low-end machines are used more, the sound quality is average, and the repair rate is low.

More realizable electronic product solution development services1. Always online network service, connected with the Internet at any time, providing convenient conditions for working at home.2. Security: intelligent security can monitor the occurrence of illegal intrusion, fire, gas leakage and emergency call in real time. Once the alarm occurs, the system will automatically send alarm information to the center, and start the relevant electrical appliances to enter the emergency linkage state, so as to achieve active prevention.3. Intelligent control and remote control of household appliances, such as scene setting and remote control of lighting, automatic control and remote control of electrical appliances, etc.4. Interactive intelligent control: the voice control function of smart home appliances can be realized through speech recognition technology; the active action response of smart home can be realized through various active sensors (such as temperature, sound, action, etc.). 5. Environment automatic control. Such as home central air conditioning system.6. Provide a full range of family entertainment. Such as home theater system and home central background music system.7. Modern kitchen environment. Mainly refers to the overall kitchen and bathroom.8. Family information service: manage family information and contact with the property management company of the community.9. Family financial services. Through the network to complete financial and consumer services.10. Automatic maintenance function: intelligent information appliances can automatically download and update drivers and diagnostic programs directly from the manufacturer's service website through the server, so as to realize intelligent fault self diagnosis and automatic expansion of new functions.

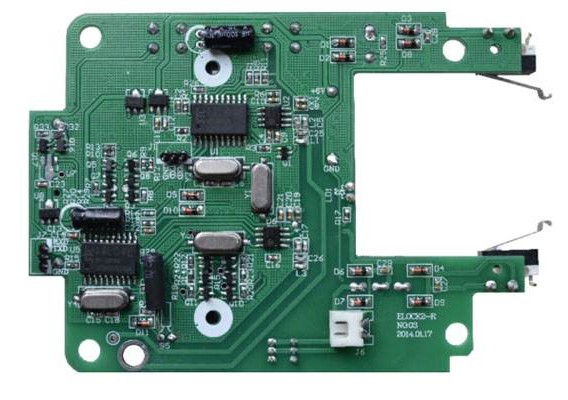

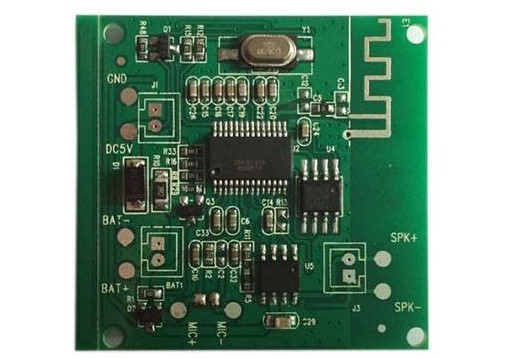

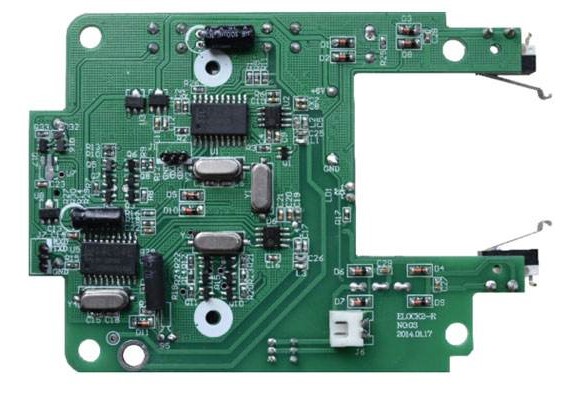

How to do project development for electronic product project development companyAccording to the customer's requirements, the system analysis is carried out first, and the software and hardware needed to realize the requirements are studied. Then choose a suitable CPU architecture based on the hardware requirements. Now the mainstream are arm, PPC, x86, MIPs, etc. after selecting the CPU architecture, choose a certain type of CPU development platform according to their own application direction.Then choose a suitable software operating system. Then the product function development is completed on the development platform. After the basic confirmation that the platform can complete the product requirements, the software and hardware development can be carried out. The hardware mainly needs to refer to the information provided by the development platform for corresponding cutting and expansion, select the specific IC model, draw the schematic diagram, PCB, plate making, welding, debugging. Then software development includes development and transplantation, underlying driver, application development and protocol development. Next, debug the equipment to see if it meets the requirement definition. Follow up testing and verification, function, performance, pressure, reliability and other aspects, in the process of software and hardware development also need to consider product testing and verification, while the hardware also needs corresponding testing and verification, such as reliability, high and low temperature, vibration and other state testing. In the process of software and hardware development, we also need to consider the product appearance design and mold development.The solution company has a certain business process when developing products for customers. According to the process of the solution company, customers can roughly understand the stage of the solution and what kind of assistance they will need from customers.

Business process of electronic product solution development1. DemandProducts exist to meet specific needs. In the early stage of development, we must conduct a comprehensive market research and project feasibility analysis. Therefore, after the user puts forward the demand, the professional engineer team of Weike technology will work with the customer to improve the preliminary analysis, functional parameters and technical indicators of the product. Ensure that the developed products fully meet the needs of users and market.2. Project initiationAfter the requirement analysis is completed, Waco technology refines the project function index from the aspects of CPU selection, power management, function module, system transplantation, driver development, mold design, etc., and conducts scheme demonstration and feasibility analysis again. After confirmation, the requirement list will be made by items and submitted to the user for verification.3. Sign the contractAfter the functions and specific indicators of the project are determined, we will quote according to the difficulty of product development, cycle and personnel input. After negotiation, the development contract was signed.4. Design and manufactureAccording to the established scheme, the specific principle design, circuit optimization, PCB wiring, debugging and welding, system transplantation, application testing and other work are carried out. In this process, we will inform the users of the progress regularly and keep full communication with the users. In addition, we will strictly control the purchase of components, PCB manufacturing and welding process to ensure the quality of products. At this stage, we will design several test prototypes.5. Prototype testThe R & D test firstly tests the prototype according to the function index in the contract to ensure that the function meets the requirements. If not, the design shall be modified until the requirements are met. After the function meets the requirements, temperature test, stability test, anti-interference test, reliability test and endurance test are carried out.6. Small batch trial productionSmall batch trial production is carried out after the prototype test is passed. The number of trial production is decided by the customer. This step is mainly to verify the consistency of the product and the reliability of the channel, and to evaluate the production cycle and possible problems in the process of mass production.7. Mass productionFormal mass production in the process of small batch production, if there is no problem, then according to customer demand for formal mass production.

What factors should be considered in the development of electronic product solutions?Industrial computer is mainly used for industrial process measurement, control, data acquisition and other work. The development of IPC should be combined with the characteristics of IPC and consider the following factors:1. ReliabilityIndustrial computer is usually used to control the uninterrupted production process. It is not allowed to shut down for maintenance during operation. Once a failure occurs, it will lead to quality accidents, even production accidents. Therefore, industrial control machines and tools are required to have high reliability, that is to say, there should be many measures to improve safety and reliability, so as to ensure that the average time between failures (MTBF) can reach tens of thousands of hours, and at the same time, shorten the fault repair time (MTTR) as far as possible, so as to achieve high operation efficiency.2. Real timeIndustrial control computer can control and monitor the production process in real time, so it is required to respond to the changes of various parameters of the control object in real time. In case of deviation or failure of process parameters, the industrial control function can respond in time and give an alarm and deal with it in real time. For this reason, industrial computer needs to be equipped with real-time multi task operating system (rtdos).3. AdaptabilityThe environment of industrial field is bad, the electromagnetic interference is serious, and the power supply system is often disturbed by the start-up and stop of equipment with large fluctuation load. The grounding system is complex, and the common mode and series mode interference is large. Therefore, industrial control machines and tools are required to have a strong ability to adapt to the environment, such as high requirements for the range of temperature / humidity changes; the ability to prevent dust, corrosion, vibration and impact; good electromagnetic compatibility, high anti-interference ability and high common mode suppression ability.4. I / O matchingIndustrial control computer should have a variety of process input and output templates, such as analog, switching, pulse, frequency and other input and output templates. It has a variety of signal conditioning functions, such as isolated and non isolated signal conditioning; various thermocouple, thermal resistance signal input conditioning; voltage (V) and current (MA) signal input and output signal conditioning, etc.5. System expansibilityWith the improvement of factory automation level, the control scale is also expanding, so the industrial computer is required to have flexible expansibility.6. System opennessThe industrial computer is required to have an open architecture, that is to say, the open principle should be observed in host interface, network communication, software compatibility and upgrade, so as to facilitate system expansion, connection of different types of computers, and software portability and interchangeability.7. Function of control software packageThe industrial control software package shall have the functions of convenient human-computer interaction, rich pictures, good real-time performance, system configuration and system generation, real-time and historical trend recording and display, real-time alarm and accident recall, etc. Besides the conventional PID (proportional, integral, differential) control algorithm, there should also be some advanced control algorithms, such as fuzzy control, neural network, optimization, self-adaptive, self-tuning algorithm, and online self diagnosis function. At present, continuous control function is often combined with intermittent control function in control software package.8. System communication functionIt has the function of serial communication and network communication. Because of the high real-time requirements, the industrial computer communication network is required to be high-speed, and meet the international standard communication protocols, such as IEEE802.4, IEEE802.3 and so on. With the powerful communication function, IPC can form a larger control system, such as DCS distributed control system, CIMS computer integrated manufacturing system, etc.9. Backup measuresIncluding power supply backup, memory information protection, manual / automatic operation backup, emergency switching device, etc.10. RedundancyIn the occasions with higher reliability requirements, industrial control computer requires dual computer operation and redundant system, including dual control station, dual operation station, dual network communication, dual power supply system, dual power supply, etc., with dual computer switching function, dual computer monitoring software, etc., to ensure the long-term uninterrupted operation of the system.

What is the scheme joint debugging of electronic product scheme development?Scheme joint debugging is a necessary process for testing the correctness and reliability of electronic product scheme development. The design of single-chip microcomputer application scheme is a rather complicated labor process. In the design and production, there are inevitably some local problems or errors. The scheme joint debugging can find out the existing problems and errors, so as to modify them in time. The process of debugging and modification may be repeated for many times, so that the trial operation of the scheme is successful and meets the design requirements.For a complex electronic product scheme development, block debugging should be carried out before scheme joint debugging. When debugging in blocks, first run the program of the module to be tuned with the help of the development scheme (or device), and observe whether the running result is consistent with the expected. If there is a problem or error, the debugging means of the development scheme (or device) should be used to find out the cause of the error or problem and eliminate it, and then run and eliminate it until the expected result is achieved.According to this step, all function modules are debugged one by one. You can also add the module that has been debugged basically correct to the new debugging module to debug together and expand one by one until all debugging is completed. On the basis of the completion of block debugging, it is ready to enter the scheme joint debugging. Firstly, the test program segments written in block debugging are removed, the functional modules are connected as a whole, and a complete application software is organized. Some peripherals are on site, so it is inconvenient to move them to the laboratory for debugging. Simulation measures can be adopted or peripherals are not connected for running debuggingAnd then gradually add. We should focus on the problems exposed only under the overall conditions.After the general debugging is correct, it is necessary to simulate various conditions and harsh environment for trial operation. On this basis, we need to run at full speed for a certain period of time to observe and test the whole scheme, so as to verify whether the function of the application scheme meets the original design requirements and whether it achieves the expected effect. In the process of joint commissioning, it mainly involves software problems, but it may also involve hardware designIn this case, the whole scheme should be considered as a whole.After the joint commissioning, it will take a period of time for the toaster and trial operation, because some hidden problems will be exposed under specific conditions, so the toaster and trial operation are necessary. The toaster should be operated in the real environment.

What are the main considerations in the overall design of electronic product scheme development?The overall design of electronic product scheme development includes the selection of main components and the division and coordination of hardware and software functions. The overall design of the scheme mainly considers the following problems.1. Determine the type of MCUAccording to the complexity, reliability, precision and speed requirements of the electronic product development, the SCM model with reasonable cost performance is selected. There are many types and models of single-chip microcomputer. The products of different models and manufacturers are different in storage capacity, Rom medium, download mode and so on.When selecting the model, we should consider: the performance of the selected model should meet the overall requirements of the scheme, and leave room for later update; the development is convenient, with good development tools and development environment; the market supply (including external expansion parts and devices) is sufficient for a long time; the designers are familiar with the development technology of the model, so as to shorten the development cycle.2. Determine the sensor usedThe selection of sensors is particularly important, because all kinds of sensors used in the industrial measurement and control scheme are still an important bottleneck affecting the performance of the scheme. A reasonable design of industrial measurement and control program often fails to reach the predetermined design index due to the constraints of sensor accuracy and environmental conditions.3. The division of software and hardware functionsThe important feature of SCM application scheme is the close combination of software and hardware. According to the actual situation of the application scheme, the division and cooperation of hardware and software functions are comprehensively considered.